color case hardening temperature

Lots of bubbles to really rile up the quench bath. Different process of case hardening.

Heat Treating Common Steels Temperature And Quenching Medium Chart

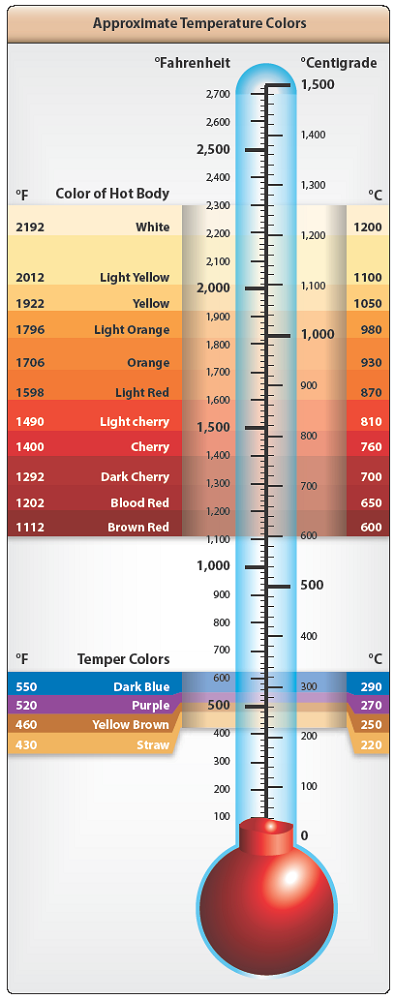

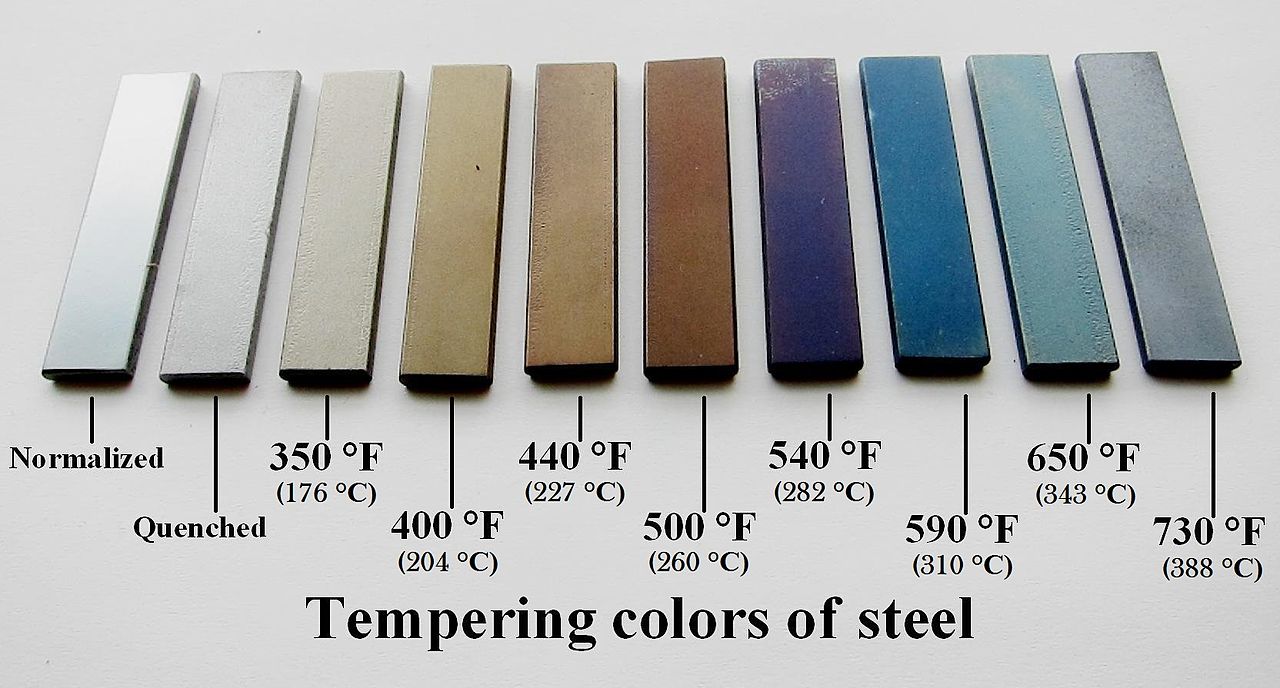

These colors were developed during tempering heat-treatment after case hardening.

. Color case hardening is done much the same way except that generally only leather and bone are used as the carbon source. You might be able to jury rig something to work in a home shop environment but youd have an almost 100 certainty of failure the first time trying. Color Case Hardening Temperatures Read 7074 times sakoman.

The fibrillated micro fibers are often used in. We keep our temperatures below hardening temperatures. Feb 20 th 2006.

Starting with yellow then blue and purple in a continuous transition. Color case hardening involves temperatures of over 1400 degrees for an hour or more. This can be done in matte or gloss.

Our color case hardening process is done with a digital controlled furnace to insure a perfect temperature with each job. Here at Tyler Gun Works we are able to Color Case items others cant due to our ability to work at lower temps. Color Case Hardening Diy.

Color case hardening sometimes referred to as case-hardening case color hardening or surface hardening is a heat treating process and one of the earliest ways of hardening lower-grade. From the earliest guns that were. You have to watch the temperature more closely with color case hardening or the colors wont come out well.

Color Case Hardening is a process for the surface hardening of steel which results in a decorative mottled-color finish. Senior Forum Member Offline Posts. COLOR CASE HARDENING READ.

Wyoming Armory is a custom gunsmithing shop where we build custom firearms but one of our specialities is tradional bone charcoal color case hardening. You have to watch the temperature more closely with color case hardening or the colors wont come out well. Most of the newer.

Color Case Hardening Temperatures. We keep our temperatures below hardening temperatures. Color case hardening temperatures read 6778 times sakoman.

Please email howell arms. Recommendations to highly polish all parts and recommendations to not ex -. Temperatures from 1250 to 1500 F and heating times of from 1 to 5 hours.

To achieve these results we use the traditional method of. They boil the item in this case the frame in a salt compound dont. Posted on january 28 2017 by brian lohman.

Comparing Induction Hardening Case Hardening 2015 08 10 Industrial Heating

Color Case Hardening Lohman Gunsmith

Guns Magazine Case Hardening Redux Guns Magazine

Color Case Hardening Turnbull Restoration

Color Case Hardening 1911forum

Difference Between Annealing Hardening And Tempering Definition Process Applications Differences

Do It Yourself Color Case Hardening Patinas Procedures For Guns Gun Parts Knife Blades Youtube

Color Case Hardening Turnbull Restoration

Color Case Hardening Yet Another Bad Idea

Color Case Hardening A Pistol Frame Armory Blog

Case Hardening Basics Nitrocarburizing Vs Carbonitriding Thermal Processing Magazine

Fundamentals Of Professional Welding

Custom Cz 75 Color Case Hardened Frame The Firing Line Forums

Color Case Hardening Yet Another Bad Idea

American Handgunner When You Re Hot American Handgunner

Color Case Hardening Photos Steel F X Patinas Color Case Hardening Photos

Henry S New Big Boy Color Case Hardened Side Gate Rifle Riflemagazine